Transport Safety

- Transport Safety Management

- Promotion Structure

- Education on Traffic Safety

- Safety Management Measures

- Operation Management (Roll Call)

- Zero Traffic Accident Movement

- Accident-Free Commendation

- G Mark Certification

(Motor Truck Transportation Business

Operator Safety Assessment Project) - Internal Driver Contest

(Nationwide Safety Competition) - Development of Head Safety Instructors

- In-car Terminals Equipped with

Communication Functionality Integrating

Drive Recorders and Digital Tachographs - Thorough Vehicle Maintenance and

Management to Support Safety

Transport Safety Management

In October 2006, following a partial revision of the Motor Truck Transportation Business Act, a traffic safety management system was introduced with the goal of having everyone from upper management to the frontline work together to build a safety management structure. This clarified “ensuring transport safety” as a duty of the business operator. Every Yamato Group company emphasizes the concept of “conducting safety management systematically and continuously through the leadership of upper management,” as indicated by the law. We have formulated safety management regulations (business operators with fleets of 300 or more vehicles are obliged to formulate and submit this to the Ministry of Land, Infrastructure, Transport and Tourism) and plans for ensuring transport safety, as well as setting a basic policy on transport safety and promoting initiatives.

Published information on transportation safety management at Group companies

Promotion Structure

Each Group company has established its own safety management system, in accordance with the safety management regulations.

In order to enhance the effectiveness of transportation safety management, we have established a system that allows organizational management through coordination between management departments and transportation personnel in the field, under the leadership of top management . Each Group company engaged in transportation safety management conducts regular reviews by top management, reviews actual performance and results, clarifies problems and issues, and improves upon any found.

We have also established a system for sharing important information—such as details of serious transportation accidents—with the ESG strategy proposal and promotion function of Yamato Holdings, which oversees the Yamato Group.

Head Safety Instructor System

The foundation of Yamato Transport's safety strategy is the head safety instructor system, which has consistently underpinned our safety since its introduction in 1974.

The head safety instructor is a specialist in safety measures, assigned to each regional branch. As of March 31, 2024, there are 369 head safety instructors nationwide. Head safety instructors patrol the Sales Offices under their supervision on a daily basis, working to ensure compliance with laws and regulations, improve the driving skills of individual drivers, and thoroughly work to prevent traffic accidents and other industrial accidents.

Other operating companies aside from Yamato Transport have also established head safety instructor systems and other similar systems.

Education on Traffic Safety

Yamato Group companies are working to improve their employees' safety awareness through regular safety education.

Internal License System

Yamato Transport drivers hired through rigorous aptitude tests receive training over the course of around one month after joining the company, and can only begin to engage in actual driving duties after obtaining their internal license. Drivers continue to refine their safe driving skills through further training one year after joining the company, regular escort guidance and road patrols by head safety instructors and managers, and driving aptitude checks conducted once every three years.

Dash Cam Video Guidance and Escort Guidance

At Yamato Transport's main branches nationwide, safety guidance supervisors and managers provide direct safety guidance to individual drivers through dash cam video guidance and escort guidance.

Dash Cam Video Guidance

Drivers gain necessary advice by watching dash cam videos, recorded while they were driving, together with safety experts and managers. This encourages behavior modification through acquisition of new awareness that enables them to become safer drivers.

Escort Guidance

Escorts accompany and observe drivers during collection and delivery, and check and instruct them in detail as to whether or not they are implementing safe and economical driving.

Creating Educational Tools

Yamato Transport uses a variety of tools to raise awareness of safety and implement its "safety first" philosophy. These include the information magazine Safety First that shares safety information, a Driver Safety Notebook carried by all drivers, and a "Safety Calendar" that can increase sensitivity to danger through hazard perception training.

We are also working to prevent accidents through a biannual initiative to achieve zero traffic accidents, using actual footage from drive recorders installed in delivery vehicles to compile a collection of "near miss" cases and create traffic safety training videos.

Driver Education Results

| Training program | Number of participants in FY2023 (persons) |

|---|---|

| Escort guidance | 25,874 |

| Guidance using drive recorder video | 47,522 |

E-Learning

Yamato Multi Charter has introduced an e-learning program about transport safety. By learning about the following two topics every month, employees are encouraged to improve their safety awareness.

Study Topics

- Guidelines for general guidance and supervision of Ministry of Land, Infrastructure, Transport and Tourism Notification No. 1366* (12 items)

- Preventing serious accidents

*Guidelines for guidance and supervision of drivers of commercial vehicles provided by motor truck (freight) transportation business operators

Safety Management Measures

In order to ensure transportation safety, we have taken various safety management measures, both across the Group and at each Group company individually, in line with our transportation safety management policies.

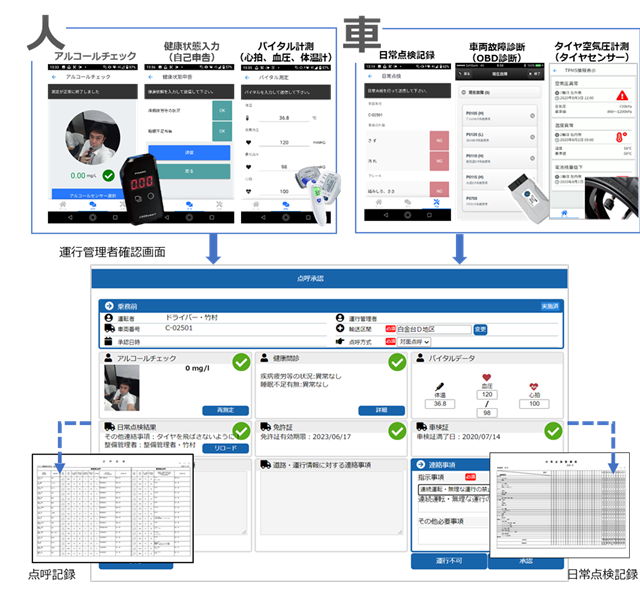

Operation Management (Roll Call)

In operation management, under Japan’s Road Traffic Act and Motor Truck Transportation Business Act, to ensure transport safety, truck transportation business operators are obliged to assign operation managers to business sites. In principle, these managers are to conduct a face-to-face roll call and give necessary instructions.

At Yamato Transport, we implemented a systematic declaration-type roll call that uses the Smart Tenko* roll call to confirm the health status of drivers from indicators such as complexion, breath, and tone of voice when responding. We also rigorously manage fatigue risks and check for the influence of alcohol using an alcohol detector. The operation manager communicates with drivers on a daily basis and can pick up on any changes in them in an effort to prevent traffic accidents caused by human error.

*We have changed from a conventional analogue management of daily inspections and roll calls to using a digital system to conduct them. The system prevents check omissions and helps to create statutory forms, increasing operational efficiency and ensuring compliance.

Zero Traffic Accident Movement

The Yamato Group conducts a group-wide Zero Traffic Accident Movement in the spring and autumn of each year, which includes overseas operating companies. Yamato Transport has been engaged in the movement since 1970.

A priority issue for the whole Group under the Zero Traffic Accident Movement is to prevent traffic accidents during driving as part of business operations. Operating companies that own vehicles have set their own themes for the movement according to the content of their specific business operations, and are engaged in initiatives to implement these priority items.

Group companies that do not have their own vehicles have also formulated their own safety measures, with priority items such as "prevention of industrial accidents" and "prevention of traffic accidents incurred by employees."

During the movement period, we summarize the state of occurrence of accidents every day for the Group as a whole, and share the current situation with Group members for a certain period. After the end of the period, we ask operating companies where accidents occurred to investigate the causes and consider measures to prevent future recurrences. In this way, we are working to raise safety awareness throughout the entire Group throughout the year.

Accident-Free Commendation

Every year, Yamato Transport, Okinawa Yamato Transport, Yamato Multi Charter, and Yamato Box Charter commend and reward drivers who excel in safe driving and continue to have no accidents.

In the FY2023, Yamato Transport also commended 2,279 locations that achieved zero accidents or disasters for a one-year period as Safety Excellence Offices.

Numbers of accident-free drivers at each company

G Mark Certification (Motor Truck Transportation Business Operator Safety Assessment Project)

G Mark (Motor Truck Transportation Business Operator Safety Assessment Project) is a certification system operated by the Ministry of Land, Infrastructure, Transport and Tourism (MLIT) which certifies business locations that achieve safety excellence. The program certifies business establishments that work actively to ensure transportation safety, from the viewpoint of making it easier for users to choose businesses that maintain high standards of safety. The Japan Trucking Association-a government-designated organization for the establishing order in the motor vehicle (freight) transportation industry-has set 38 assessment criteria, based on which business operators are certified by the organization's safety evaluation committee.

The Yamato Group is actively acquiring G Mark certification to improve transportation safety.

For details of G Mark certification status at each company, please see our ESG data.

Internal Driver Contest (Nationwide Safety Competition)

With the aim of improving the driving safety of its professional drivers, maintaining Groupwide safety awareness, and improving driving techniques, Yamato Transport has continued to hold the Yamato Group Nationwide Safety Competition since 2012. In FY2023, 36 drivers were chosen from over 60,000 across five Yamato Group companies to compete over safe driving skills and knowledge.

Development of Head Safety Instructors

Yamato Transport provides leadership training to head safety instructors and specialist head safety instructors are certified twice a year. Step 1 (laws and regulations), Step 2 (driving skills), Step 3 (observation skills), and Step 4 (leadership) certification tests are held, and it is determined whether the head safety instructors have the necessary skills.

| Certification step | Number of people certified in FY2023 (persons) |

|---|---|

| Step 1 (laws and regulations) | 329 |

| Step 2 (driving skills) | 326 |

| Step 3 (observation skills) | 309 |

| Step 4 (leadership) | 304 |

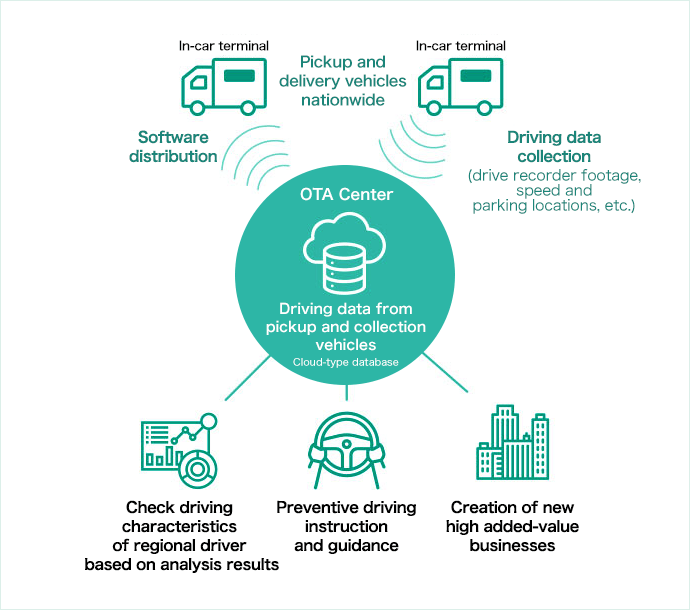

In-car Terminals Equipped with Communication Functionality Integrating Drive Recorders and Digital Tachographs

Yamato Transport has installed integrated terminal devices in all pickup and delivery vehicles to collect driving data, such as footage collected from drive recorders and driving routes created using information obtained from GPS antennas, in addition to the speed and parking position information already collected by digital tachographs. The data collected by these devices is automatically sent via communications network connections and stored in a cloud-type database in real time. We have also enabled automation in registering "near miss" locations, labor saving for drive start and endpoint settings, and automation of software updates for in-car devices, so that sales drivers can concentrate more on safe driving.

Visualizing and analyzing the driving data collected and centrally managed via these in-car devices, it is possible for head safety instructors and other relevant personnel to more accurately grasp specific details of the driving characteristics of each sales driver. As a result of this, we will be able to provide more finely tuned preventive safe driving training tailored to the individual driving characteristics of each driver.

Thorough Vehicle Maintenance and Management to Support Safety

Yamato Autoworks covers over 3,700 Yamato Group collection and delivery locations, and is responsible for the inspection and maintenance of around 46,000 vehicles. The company has 72 maintenance plants located around Japan, 30 of which are Super Works locations: state-of-the-art factories that pursue greater efficiency of vehicle maintenance systems, consideration for the environment, and ease of work for employees.

Most of these maintenance plants-including Super Works locations-are open 24 hours a day, 365 days a year, and perform statutory periodic inspections on all vehicles by centralized management throughout the year, in addition to rapid response in the event of breakdowns. By continuously checking the status of vehicles and accumulating information, the company also achieves preventive maintenance, performing maintenance on vehicles before breakdowns occur. Of the approximately 930 mechanics, around 700 are qualified automobile inspectors who can perform completion inspections after maintenance work has been completed to ensure that vehicles comply with safety standards. In maintenance, the accuracy of inspections is improved through double-checking conducted by another mechanic, for both midway and completion inspections.